- High gold recovery realized with conventional processing techniques demonstrates the non-refractory nature of gold mineralization at Valley

- Average gold recovery from non-optimized methods ranges from 87.6% (average bottle roll cyanidation) to 95.7% (average carbon-in-leach)

- Strong buffering effect and low concentrations of deleterious elements carry positive implications for environmental aspects of processing, reclamation and closure

- Results open the door to multiple future processing options for Valley mineralization.

Vancouver, B.C., June 14, 2023: SNOWLINE GOLD CORP. (TSX-V: SGD) (OTCQB: SNWGF) (the “Company” or “Snowline”) is pleased to announce results from initial, first-pass metallurgical testing of gold mineralization from the Valley discovery on its Rogue Project, Yukon Territory, Canada. Ten composite drill core samples representing various locations and grades within the Valley gold system were subject to bottle roll cyanidation, carbon-in-leach (CIL) and preliminary flotation amenability testing. Gold recovery from test work was favourable varying from 81% to 99% across a range of head grades, material size and metallurgical approach (Figure 1). The results demonstrate that mineralization at Valley is non-refractory and highlight the applicability of multiple processing techniques as options for further consideration.

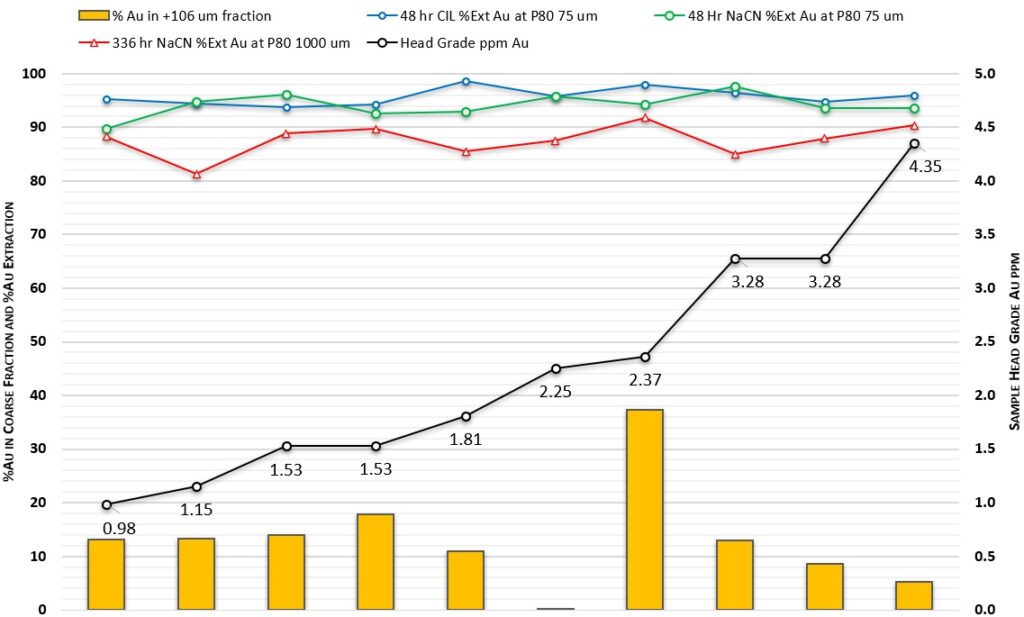

Figure 1 – Gold recovery rates by bottle roll cyanidation (red, left axis), carbon-in-leach (blue, left axis) and non-optimized floatation (green, left axis) across 10 composite drill core samples sorted by head grade (black, labelled with grams per tonne gold, right axis). Yellow bars indicate proportion of gold in particles >0.106 mm in size (left axis), an indicator for proportion of gravity recoverable gold.

“These positive initial metallurgical results mark an important milestone in the advancement and de-risking of our Rogue Project’s Valley discovery,” said Scott Berdahl, CEO & Director of Snowline. “The gold system at Valley has already demonstrated considerable scale, consistency in strong gold grades, and a simple near-surface geometry favourable to mining. Now we can attest confidently and quantitatively to its positive metallurgical properties as well. Gold is highly recoverable by various processing methods. The mineralization is naturally buffered and low in deleterious elements. Valley is a discovery that continues to deliver above expectations. With a third drill now turning on site, this is a terrific kick-off to our 2023 field season. We are excited to continue to advance both the Valley discovery and the broader, district-scale Rogue Project with our ongoing drill and surface campaigns.”

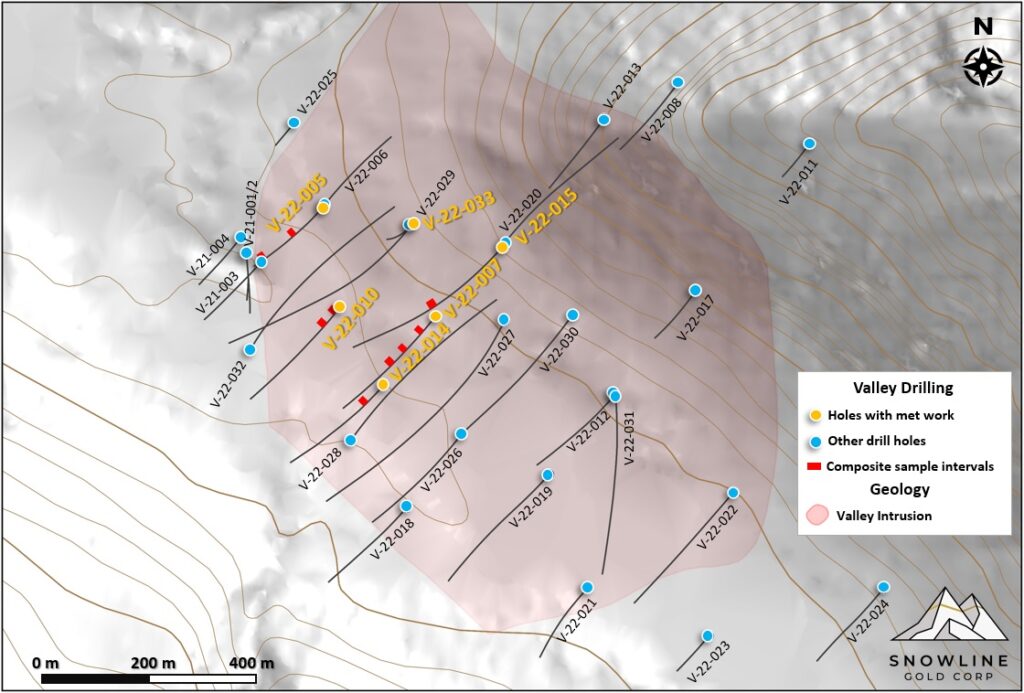

Figure 2 – Plan map of metallurgical sample locations from the Rogue Project’s Valley target. Each composite drill core sample represents a continuous stretch of drill core from 21 m to 26 m in length. The samples covered a variety of gold grades, host rock lithology and physical location, with samples taken from across an area of roughly 200 x 300 m, and from bedrock surface to a vertical depth of roughly 260 m. All metallurgical samples represent fresh (non-oxide) mineralization.

METALLURGICAL TESTING

The Company submitted ten composite samples of drill core, approximately 10 kg each, from the Rogue Project’s Valley target to McClelland Laboratories in Sparks, Nevada for analysis. Each composite sample was taken from a contiguous interval of drill core within the Valley intrusion (Table 1), with contribution weighted by individual sample length to create a proportional representation of material along each composite interval. The spatial distribution of samples is shown in Figure 2. Specific gold extraction techniques and other parameters of the testing are outlined in the following sections.

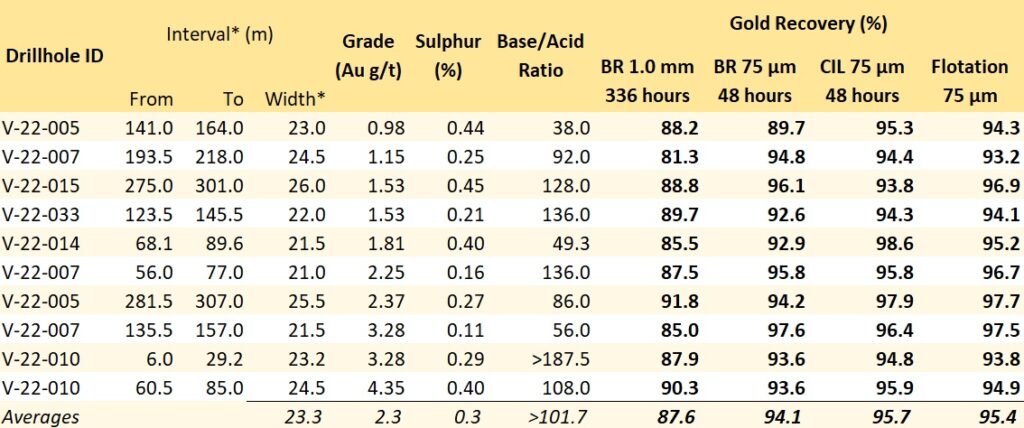

Table 1 – Gold recoveries and acid/base accounting results from initial metallurgical testing on the Rogue Project’s Valley target. Recoveries range from 81.3% to 98.6% across all methods and demonstrate non-refractory mineralization amenable to multiple processing methods. BR = bottle roll testing, CIL = carbon-in-leach. 1.0mm and 75 µm indicate crush sizes, with 80% of material passing through a mesh of the given size. Base/Acid Ratio is the ratio of acid neutralizing potential per unit weight versus acid generating potential per unit weight. The >>1 values in this column demonstrate a strong natural buffering effect. *Drilled lengths are presented, true widths have not been determined.

Composite sample gold grades ranged from 0.98 g/t Au to 4.35 g/t Au with sulphur contents from 0.11% to 0.45%. The average sulphur content associated with >0.5 g/t Au mineralization in 2022 drilling at Valley is 0.39% S. Future metallurgical testing will include additional variability samples from any minor, localized structures within the Valley system associated with higher sulphur content.

Natural buffering of the host rock and low concentrations of deleterious elements greatly simplify process chemistry, reduce environmental risk and support viable reclamation and closure options. Together, these results should provide for a high degree of flexibility in realizing and optimizing the economic value of the Rogue Project’s Valley discovery.

The strong amenability of gold mineralization to extraction applying various conventional metallurgical and operational techniques opens the door to multiple process alternatives.

Bottle Roll Testing

Cyanidation bottle roll testing provides a qualitative indication as to the heap leachability of gold mineralization. For Valley system samples, initial testing on exploration composites considered a material size of 80% passing 1.0 mm, with gold recovery rate kinetics monitored over the course of 336 hours (2 weeks). Average gold recovery was 86.7%, with results for individual composites ranging from 81.3% to 91.8%. Rate kinetics were encouraging, with an average of 65% of recoverable gold values achieved within the first 6 hours of testing, and an average of 82% of recoverable gold within 48 hours. At the end of the two-week test, diffusion-controlled metal recoveries were still increasing, suggesting that further incremental gains in gold recovery are likely when considering prolonged leach cycle times on a leach pad at coarse crush size.

An additional set of cyanidation bottle roll tests was pursued on the same composite samples at a material size of 80% passing 75 microns. Realized gold recoveries averaged 94.1% within 48 hours, with recoveries from individual composite samples varying from 89.7% to 97.6%. Gold extraction rate kinetics were rapid with 90% of recoverable gold values extracted within the first 6 hours supporting the applicability of either Grind-CIP or Grind-CIL process alternatives.

Cyanidation and Carbon Adsorption

Cyanidation and carbon adsorption could potentially play a role on the project with either heap leaching and a Carbon-in-Column circuit for the adsorption of gold from heap solution, or in conjunction with Grinding followed by a conventional cyanidation and Carbon-In-Leach circuit (CIL) or a Carbon-In-Pulp circuit (CIP).

CIL bottle rolls at 80% passing 75 microns averaged 95.7% over a 48-hour period, with individual composite samples varying from 93.8% to 98.6% Au recovery.

The implementation of a grinding circuit could also be followed by gravity concentration with flotation of remaining values to a rougher concentrate, and high intensity cyanidation of the concentrate, followed by a Carbon-In-Pulp circuit (CIP). These processes are all conventional, using well defined technology that is widely applied across the industry.

Flotation

Flotation conditions were selected to define the expected deportment of gold values along with sulfide mineralization. In addition, the recovery of free native gold and gold alloys was pursued applying specific precious metal promoter-collectors.

Test results were very favorable realizing 93.2% to 97.7% Au recovery (average 95.4% Au recovery) to a rougher concentrate at an average 15% mass pull along with 70-90% recovery of sulfides present.

A low weight percentage rougher concentrate enables regrinding and the pursuit of additional flotation cleaner stages to produce a final concentrate for off-site processing, or alternatively, for fine grinding and on-site cyanidation of the concentrate to achieve consistently high gold recoveries.

Gravity

Metallic fire screen assays at 100 microns indicated an average 13.3% content of gravity recoverable gold, with individual composite results ranging from 0.2% to 37.2%. The sample with the highest proportion of gravity recoverable gold, V-22-005 from 281.5 m to 307.0 m downhole, showed strong total recoveries by all other metallurgical methods as well.

Environmental Aspects

Acid/base accounting of the composite samples establishes potential acid generating sulphide content relative to the neutralizing potential of carbonates present in the rock. The composite samples from Valley showed a strong buffering effect, with 38 to 190 times (average 102 times) the amount of neutralizing potential compared to acid generating potential applying the modified Sobek methodology for ABA accounting. Specific values for acid generating potential (in units of tons CaCO3 equivalents per 1000 tons of solids) ranged from <0.3 to 0.9, compared to neutralizing potential (also in units of tons CaCO3 equivalents per 1000 tons of solids) ranging from 17.5 to 57.5. Valley Zone mineralized material has been demonstrated to be naturally and strongly buffered, greatly reducing the potential for acid mine drainage, and expanding the scope of viable possibilities for effective processing, reclamation and closure.

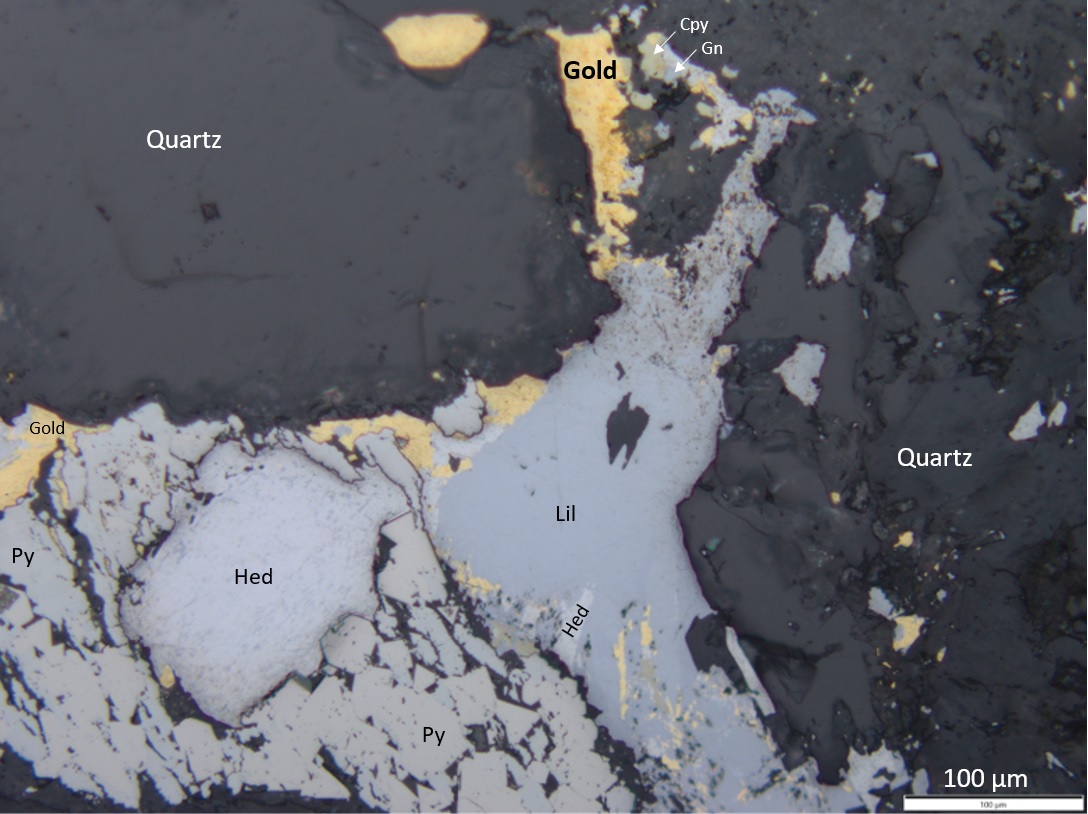

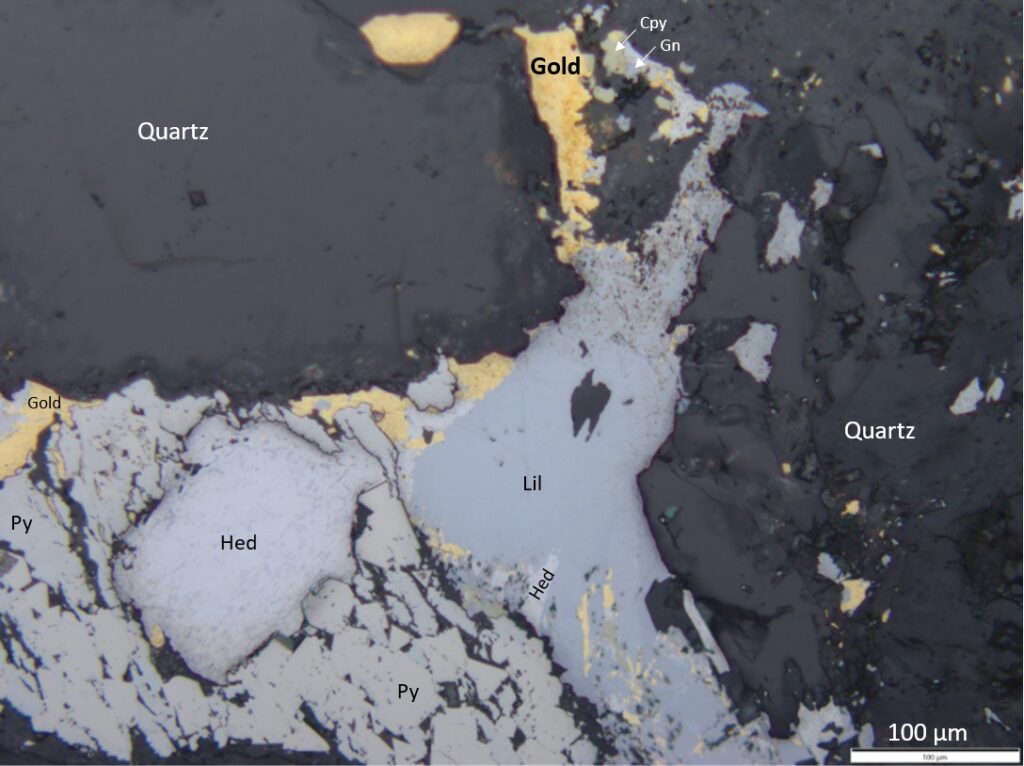

Figure 3 – Reflected light micrograph of abundant gold grains in V-22-007 at 269.8 m downhole. Gold occurs primarily in its native form, as fine grains along grain boundaries near small clusters of sulphides minerals in quartz veins. Scale bar (bottom right) shows 100 microns, or 0.1 mm. Py=Pyrite (FeS2), Cpy=Chalcopyrite (CuFeS2), Gn=Galena (PbS), Hed=Hedleyite (Bi7Te3), Lil=Lillianite (Pb3Bi2S6).

Oxidation State

Metallurgical testing on the Rogue Project’s Valley target focused on “fresh,” or non-oxidized, zones. Owing to the geologically recent glaciation of the Rogue Project area, the Valley gold system does not appear to have any significant oxidized zones. Mineralization observed in drill core to date is generally fresh rock below a few metres from bedrock surface. Similar to other RIRGS systems, such as Kinross’s Fort Knox Mine in Alaska, the high proportion of native gold at Valley and the nature of its distribution allow for effective recovery of gold from fresh rock by various means (Figure 3). At Fort Knox specifically, this has allowed the operators to mine and profitably extract gold primarily from fresh rock using mineral reserve cut-off grades of 0.1 g/t Au (source: Fort Knox Mine NI 43-101 Technical Report effective June 11, 2018).

Next Steps

Material from 2023 metallurgical testing has been sent for analysis of gold deportment within the mineralized rock. The characterization of gold grain size distribution and mineralogical associations will help to optimize gold recovery processes and to confirm and improve the understanding of metallurgical performance while supporting metal recovery modeling.

Additional metallurgical test work contemplated by the Company would expand the existing knowledge base to include lab-scale heap leach columns at various crush sizes, CN bottle rolls, Grind-CIL testing, as well as flotation-cyanidation testing to thoroughly investigate applicable process alternatives and associated performance.

EXPLORATION UPDATE

A third drill has commenced operation on the Rogue Project’s Valley discovery, and the 15,000+ m drill program at Rogue is ongoing. To date, 1,927 m have been drilled so far on the Valley target in 2023, with 3 holes completed and an additional 3 holes in progress. Initial drill core samples have been submitted for analysis. Analytical results for all holes drilled in 2023 are still pending.

ABOUT ROGUE

The Valley Zone on Snowline’s flagship Rogue Project is a newly discovered, bulk tonnage style, reduced intrusion-related gold system (RIRGS), with geological similarities to multi-million-ounce deposits currently in production such as Kinross’s Fort Knox Mine in Alaska and Victoria Gold’s Eagle Mine in the Yukon. Early drill results demonstrate unusually high gold grades for such a system, present near surface across drill intersections of hundreds of metres. Gold is associated with bismuthinite and telluride minerals hosted in sheeted quartz vein arrays within and along the margins of a one-kilometer-scale, mid-Cretaceous aged Mayo-series intrusion. Valley is an early-stage exploration project without a resource estimate, and while initial results are encouraging, the presence or absence of an economically viable orebody cannot be determined until additional work is completed.

The Rogue Project area hosts multiple intrusions similar to Valley along with widespread gold anomalism in stream sediment, soil and rock samples. Elsewhere, RIRGS deposits are known to occur in clusters. The Rogue Project is thus considered by the Company to have district-scale potential for additional reduced intrusion-related gold systems.

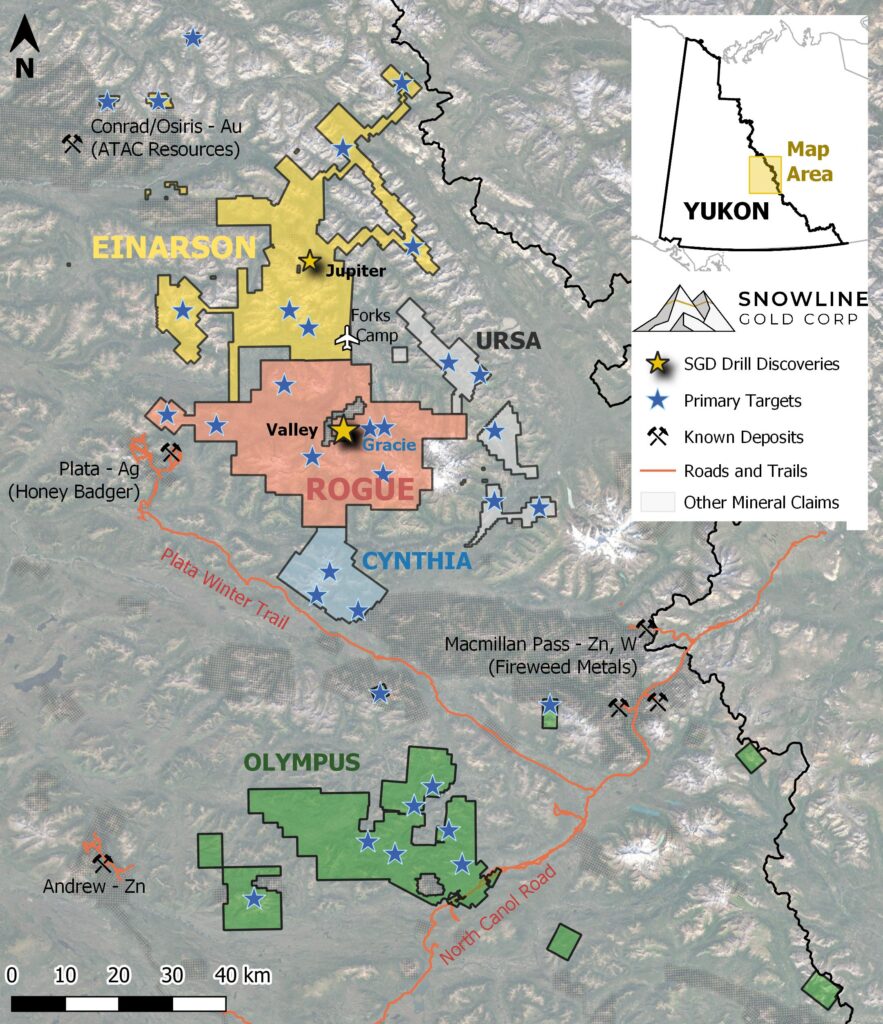

Figure 4 – Project location map for Snowline Gold’s eastern Selwyn Basin properties: Rogue, Einarson, Ursa, Cynthia and Olympus. The current work program at Rogue is based from the Company’s Forks Camp.

ABOUT SNOWLINE GOLD CORP.

Snowline Gold Corp. is a Yukon Territory focused gold exploration company with an eight-project portfolio covering >333,000 ha. The Company is exploring its flagship >94,000 ha Rogue gold project in the highly prospective yet underexplored Selwyn Basin. Snowline’s project portfolio sits within the prolific Tintina Gold Province, host to multiple million-ounce-plus gold mines and deposits including Kinross’ Fort Knox mine, Newmont’s Coffee deposit, and Victoria Gold’s Eagle Mine. The Company’s first-mover land position and extensive database provide a unique opportunity for investors to be part of multiple discoveries and the creation of a new gold district.

QUALIFIED PERSON

Information in this release has been prepared under supervision of and approved by J. Scott Berdahl, M.Sc., P. Geo., CEO and Director for Snowline Gold, and Steve Haggarty, P.Eng, Director and CEO for Haggarty Technical Services, as Qualified Persons for the purposes of National Instrument 43-101.

ON BEHALF OF THE BOARD

Scott Berdahl

CEO & Director

For further information, please contact:

Snowline Gold Corp.

+1 778 650 5485

info@snowlinegold.com

CAUTIONARY NOTE REGARDING FORWARD-LOOKING STATEMENTS

This news release contains certain forward-looking statements, including statements regarding future mineral processing options, closure and reclamation plans, future metallurgical testwork, the potential for investors to participate in multiple future discoveries, the Rogue project having district-scale prospectivity, the creation of a new gold district and the Company’s future plans and intentions. Wherever possible, words such as “may”, “will”, “should”, “could”, “expect”, “plan”, “intend”, “anticipate”, “believe”, “estimate”, “predict” or “potential” or the negative or other variations of these words, or similar words or phrases, have been used to identify these forward-looking statements. These statements reflect management’s current beliefs and are based on information currently available to management as at the date hereof.

Forward-looking statements involve significant risk, uncertainties and assumptions. Many factors could cause actual results, performance or achievements to differ materially from the results discussed or implied in the forward-looking statements. Such factors include, among other things: risks related to uncertainties inherent in drill results and the estimation of mineral resources; and risks associated with executing the Company’s plans and intentions. These factors should be considered carefully, and readers should not place undue reliance on the forward-looking statements. Although the forward-looking statements contained in this news release are based upon what management believes to be reasonable assumptions, the Company cannot assure readers that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this news release, and the Company assumes no obligation to update or revise them to reflect new events or circumstances, except as required by law.